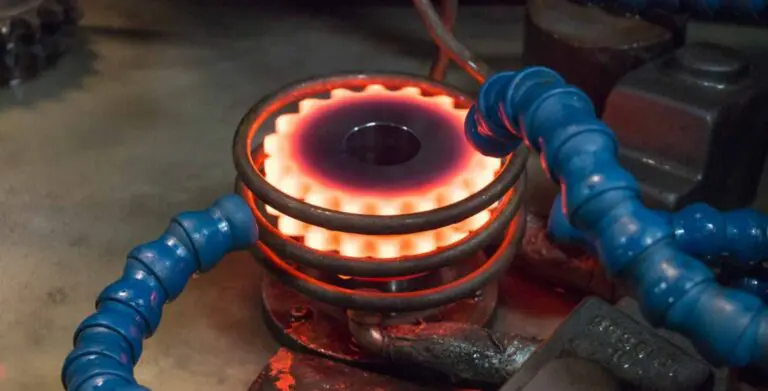

Induction Hardening

INDUCTION HARDEN SPECIFIED AREAS USING ELECTROMAGNETIC TECHNOLOGY

Induction hardening is a type of surface case hardening surface process that can be used in an isolated zone/area or harden the entire surface of a part. The process uses electromagnetic induction to rapidly heat and then quench specific/entire areas of a metal part. This creates a very hard outer “case” while leaving the inner “core” tough and ductile.