Carburizing and Carbonitriding

Utilize the power of our atmospheric ovens to case harden your steel

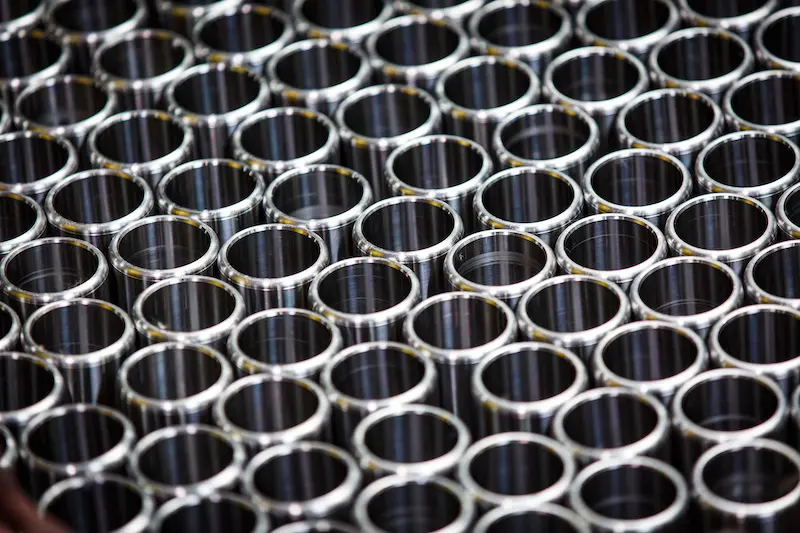

Carburizing, also known as case hardening, is a heat treatment process that significantly improves the performance of metal parts by creating a hard, wear-resistant surface while maintaining a tough, ductile core. This process is particularly beneficial for low-carbon steel components that would otherwise be too soft for demanding applications.

Carbonitriding is a similar heat treatment process that improves the surface hardness and wear resistance of steel by diffusing both carbon and nitrogen into its surface. It’s essentially a modified version of carburizing that introduces nitrogen, typically from ammonia gas, along with carbon. This process is used to give an even harder surface than carburizing if your specifications dictate for it.

Key Benefits of Carburizing

Carburizing and Carbonitriding are most often used on low-carbon steels to give them a hard, durable outer layer, or “case,” while the core remains soft and tough. This combination of properties makes carbonitrided parts highly resistant to friction and fatigue. The most commonly used steel materials for carburizing or carbonitriding are: 1018 , 8620, 1214,1018, A36, mild steels, and low carbon steels